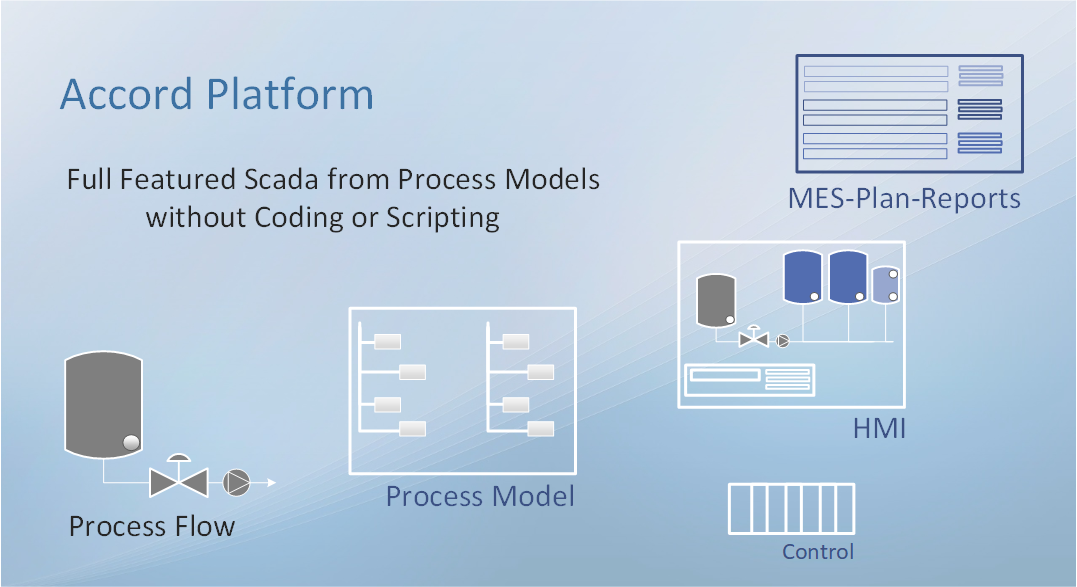

Accord provides fully integrated systems with unified logic, visualisation and management, in a manner that is easy to understand and modify.

The Process Model configuration is used to provide PLC Control, Visualisation, Operations Management and Reports using appropriate Modules, HMI tools and controls, and faceplates in a safe and reliable method.

Accord provides object representation for the physical objects in a plant and also for sequences/phases/programs. The method is one of selections from lists and limited sufficient configuration with emphasis on ease-of-use.

Development and Production Environments:

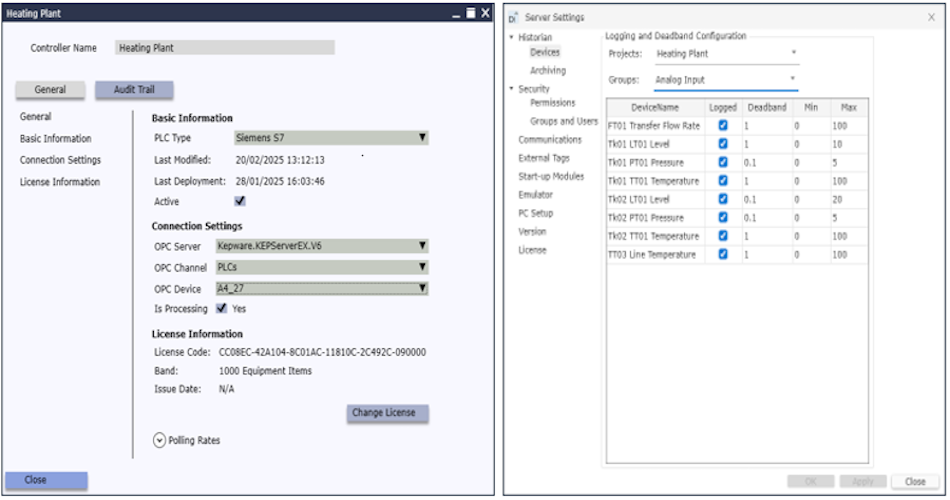

The Development Environment allows development of Process Models and HMI’s, with testing on PLC Emulator and Simulator and generation of Process Design and Test documents. The Production Environment provides connection to PLC’s (through OPC Servers) instead of Emulators, and HMI Clients. Redundancy and Data Integrity modules can also be enabled. Recipe, Plan/MES and Audits can be used in either environment. The software is the same in both environments, the choice is made to make the functionality clearer.

Modules:

| Development – Available ? | Production – Available ? | ||||

| Designer | Designer | Configure Process Models and HMI Clients | Yes | Yes | |

| Relay | Transfer Values between PLCs | Yes | Yes | ||

| Emulator | Running Models on PC as if on PLC, for testing and training. | Yes | |||

| Simulator | Simulation of Plant values for Testing in Emulation. | Yes | |||

| Service | Server | Data Management and services for all modules. | Yes | Yes | |

| Redundancy | Hot Standby Auto Switchover server setup | Yes | |||

| PLC | Library | Auto Implementation of Process Model in Controller. | Yes | ||

| Operation | HMI Client | PC HMI client application, interacting with Server module. | Yes | Yes | |

| Manager | Recipe | Configuration of Recipes for Setpoints, Step Times and Selections. | Yes | Yes | |

| MES/Plan | Sequencing of Programs, or Plans, with Recipe selection. | Yes | Yes | ||

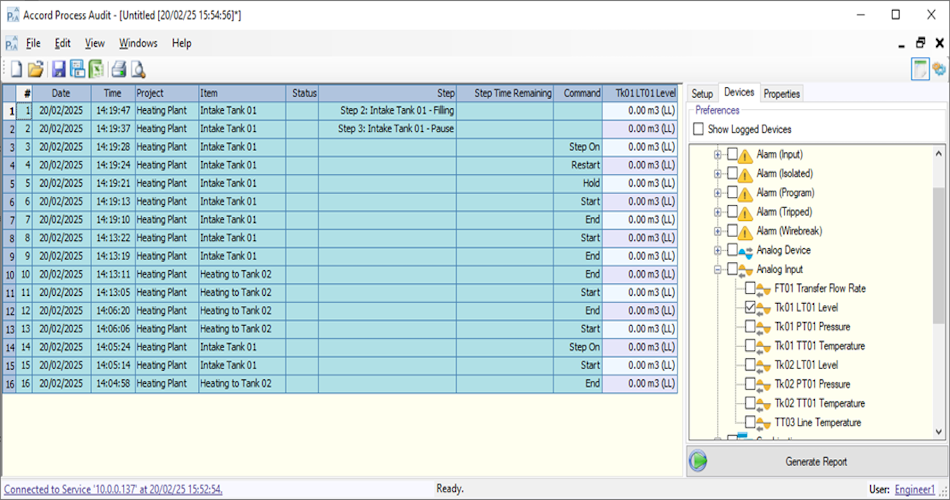

| Process Audit | Query of logged status and activity; configurable using selections / drop down. | Yes | Yes | ||

| Security Audit | Listings of previous commands and actions from HMI; by operator, or from Module. | Yes | Yes | ||

| Custom Reports | User Configurable reports, with embedded program information and trends | Yes | Yes |

Please also See Installation for note on Development and Production Environments

….

Project General Stages:

This is an introduction summary for the method and setup.

Design of Process Models and HMI:

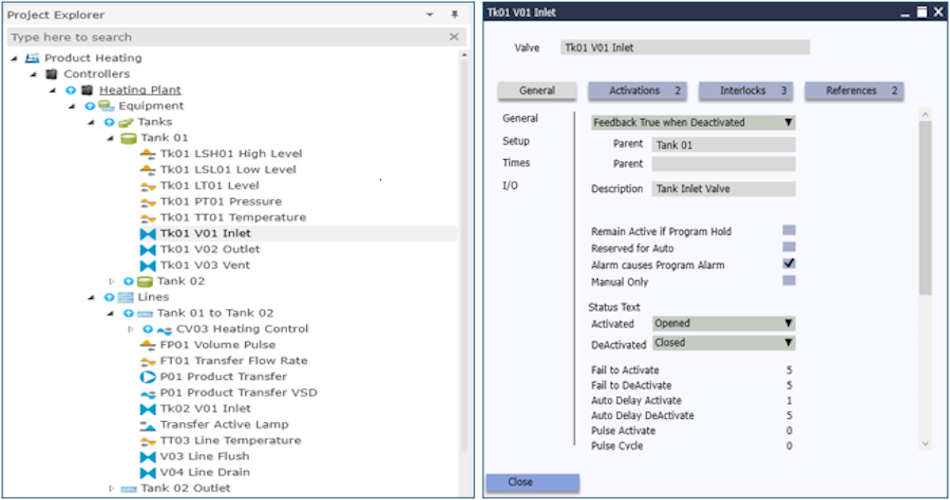

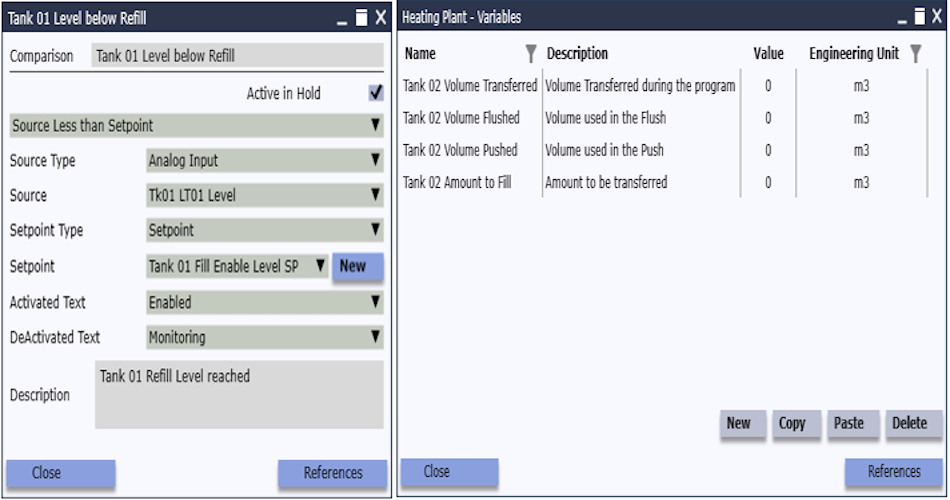

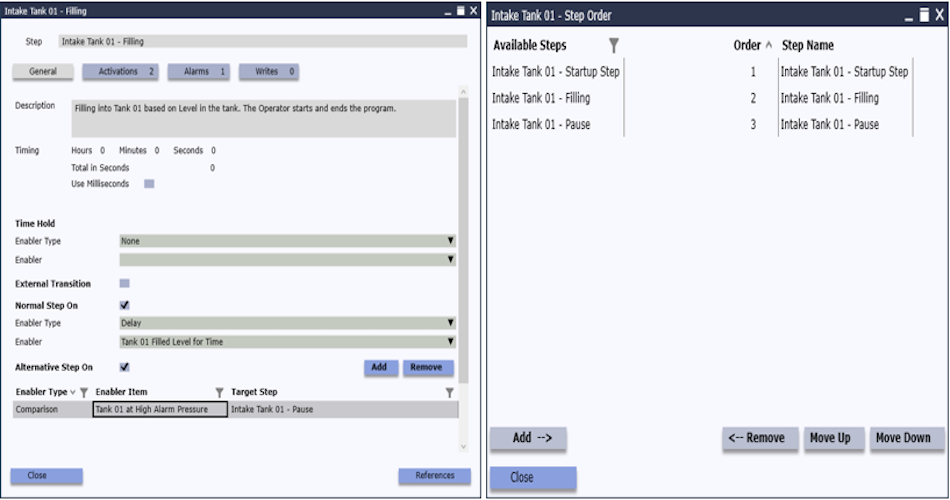

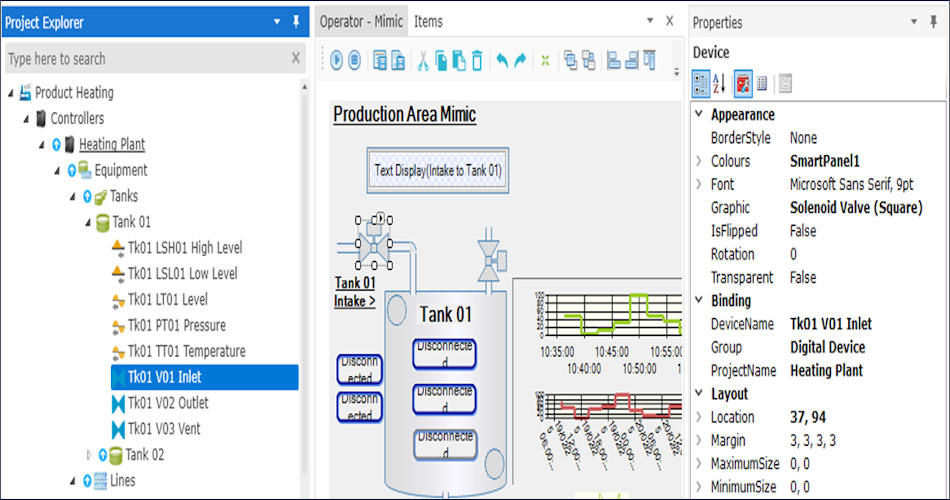

Equipment objects are configured in Units, for device type. Programs are set up, as lists of steps, and usual automation items such as comparisons and selections for activations are configured and selected using drop-downs. HMI apps are built by placing device and list objects onto the screens and the setup and the system can be tested using PC emulator.

…

Implementation in a PLC:

After testing the configuration is downloaded to a PLC which contains the Accord PLC Runtime library which implements the control system from the Model. Each object is processed, either in turn, or due to a link.

The PLC method works with configured item data and references. All associations are implemented automatically without any additional coding.

The PLC Runtime Library is usually copied into the overall PLC project (containing hardware layout etc) using standard PLC Editor.

…

Data and User Management:

The Server module assigns the addresses to PLC data and automatically makes relevant data available for HMI and other modules with correct read/write properties and limits for any value settings. Server also manages security so that only relevant settings are available for users.

The module communication is carried out using fast, secure MS WCF software. Audit entries for every operator action and also for selected (logged selection) process value or event are stored automatically.

…

Visualisation:

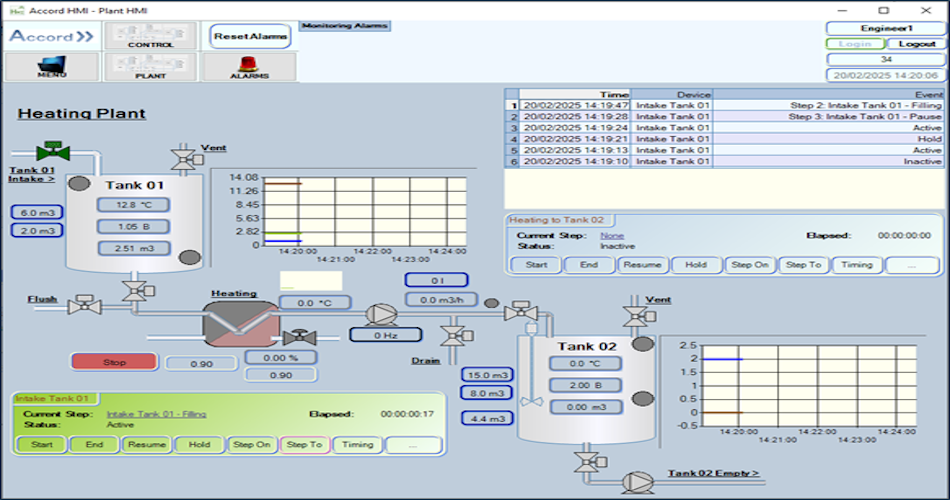

The HMI client is just a client of Server, and can easily be installed on a networked PC. The configuration of the HMI screens is stored in Server database and is transferred to the client PC when the HMI software is started. All limits, states and security functions are automatically up-to-date on every client PC.

…

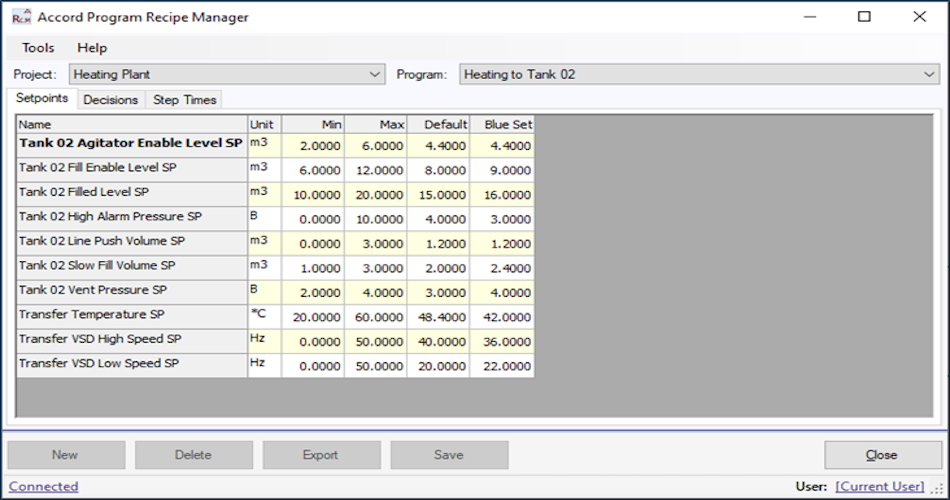

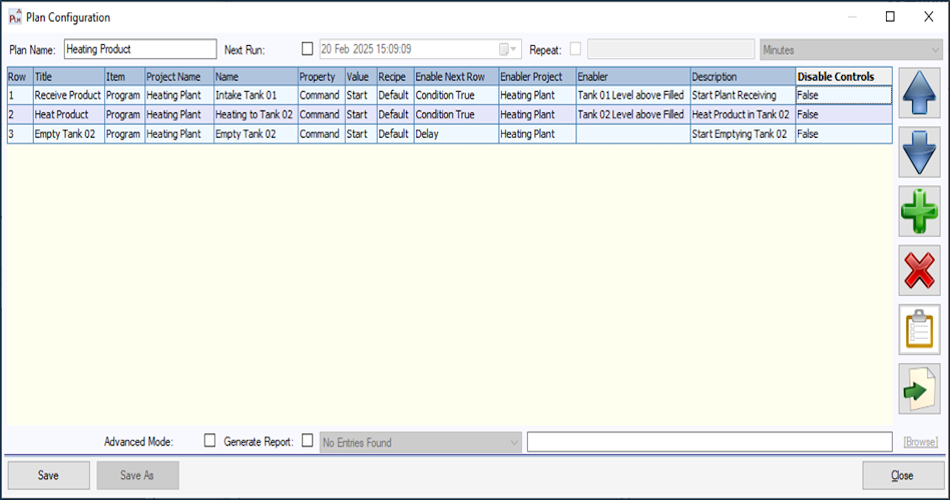

Managing Recipes & Automatic Program Execution:

These modules are also clients of the Server, and can be installed separately on client PC’s, with just configuration required for the instance they are being used for.

…

Auditing Historical Information:

The Process and Security audits provide the ability to examine any past status or event. Again, they are clients of server and in effect perform large configurable queries of the process database, converting the settings to SQL Query and returning the data into the framed tables.

…

Putting in a Hot Standby:

A second PC can act as a hot-standby (auto-switchover) backup for the Server PC. The selection of the functions as Primary and Partner and the linking is carried out using a drop-down and search, once the two PC’s are on same network. If the Primary fails the Partner will automatically poll PLC’s and provide information for the clients. The Partner PC updates historical data in the Primary PC when it restarts.

…

Quick Screenshot type introduction :

please use the arrows ->

Installation and Pricing:

Accord is provided as Development and Production Environments.

The Development Environment allows development of Process Models and HMI’s, with testing on PLC Emulator and Simulator and generation of Process Design and Test documents. The Development Environment is provided as an annual licence with full support.

The Production Environment provides connection to PLC’s (through OPC Servers) instead of Emulators, and HMI Clients. Redundancy and Data Integrity modules can also be enabled. The Production Environment is quoted as perpetual licence and support can be quoted also.

The software is the same in both environments, the choice is made to make the functionality clearer, just through Emulator or PLC access in Designer. Recipe, Plan/MES and Audits can be used in either environment.

Accord is priced for mid range; an Accord project should be significantly cheaper for licences than any large brand PCS systems, and also significantly cheaper for development than a standard PLC/HMI project due to the savings in development and documentation.

Pricing for any requirements is available from Logicon Ireland. Logicon may direct to other regional partners also.