Design of Process Models and HMI

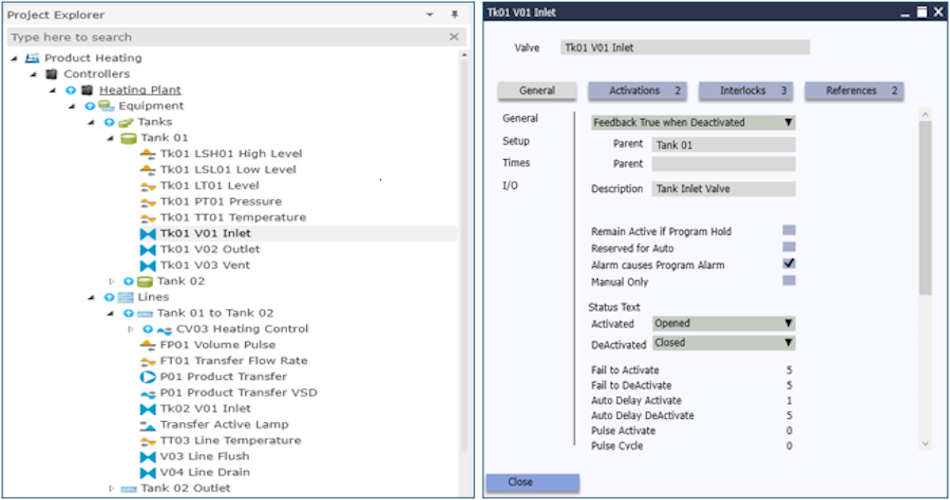

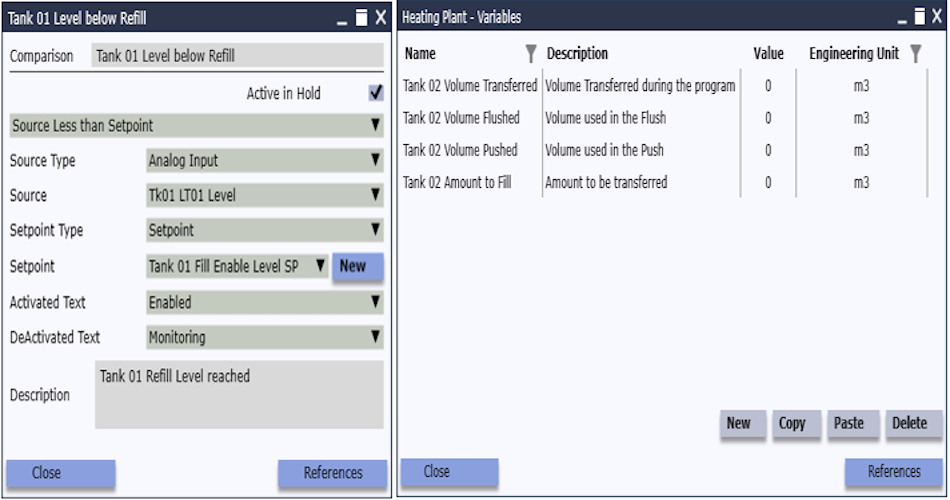

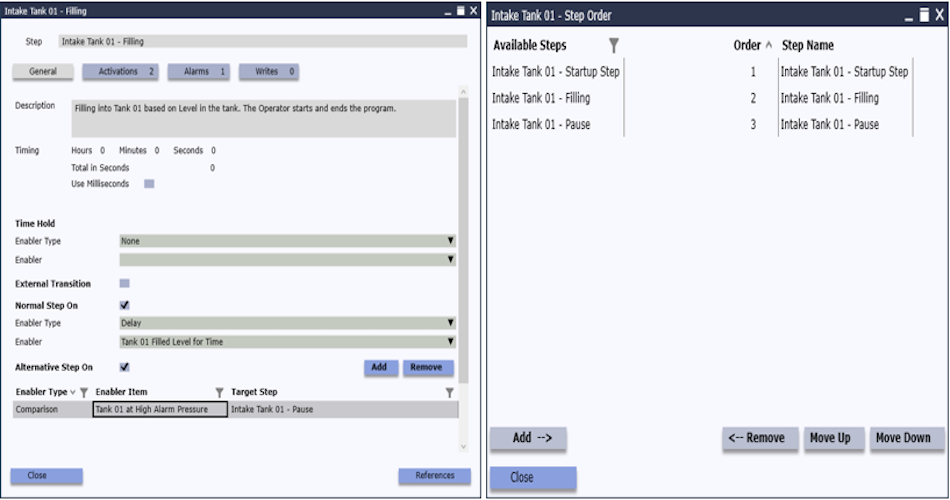

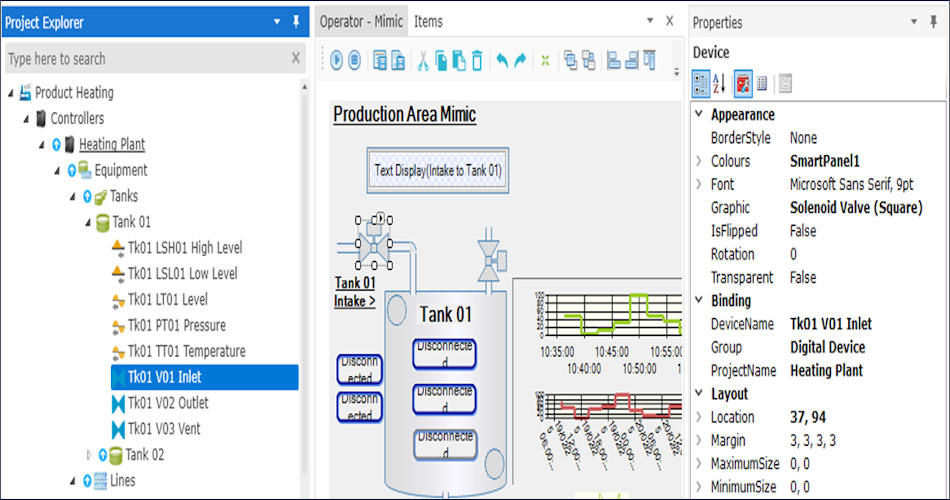

The Settings for each of the Equipment and Program objects are configured in Designer. The sections relating to linking with other objects are filled out by selection from tailored drop-down lists. The objects are immediately available for placing on Mimic Screens, and the system can be tested easily from the mimic using the emulator.

Implementation in a PLC:

After testing the Model configuration is downloaded to a PLC which hosts the Accord PLC Runtime library which contains routines for monitoring and control of objects and uses the settings data in the objects in the Model to implement the control system. The number of objects and the links between the objects are looked up and used in the implementation. The library does not compile to make a new program; the program is always fixed and stable.

The PLC method works by looking up the type and identity of the configure item. For example, if a Valve is configured to be interlocked by a Low Level switch the code will look up the current state (timed result) of the Switch and apply the Interlocked State to the valve if the Low Level is present. all configurations like this are looked up and implemented by the library.

We supply the PLC Runtime Library, to be copied into the the installed PLC project using PLC Editor.

…

Data and User Management:

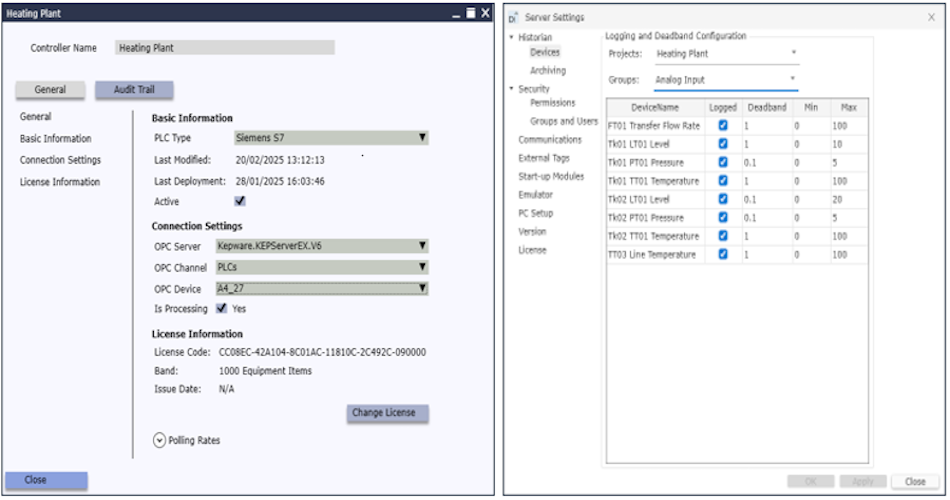

The download of model configuration data to the PLC is carried out by the Server module, and it then knows the address of all the object data in the PLC and automatically. Server makes the object data available for all modules; HMI, Recipe etc with correct read/write properties and limits for any value settings. Server and also manages security so that only relevant settings are available for users.

Server functions are enabled and managed within Designer. Server uses MS WCF technology to provide fast comprehensive communication with HMI Clients and other modules. Server automatically writes audit entries for every operator action and also for selected (logged selection) process value or event.

…

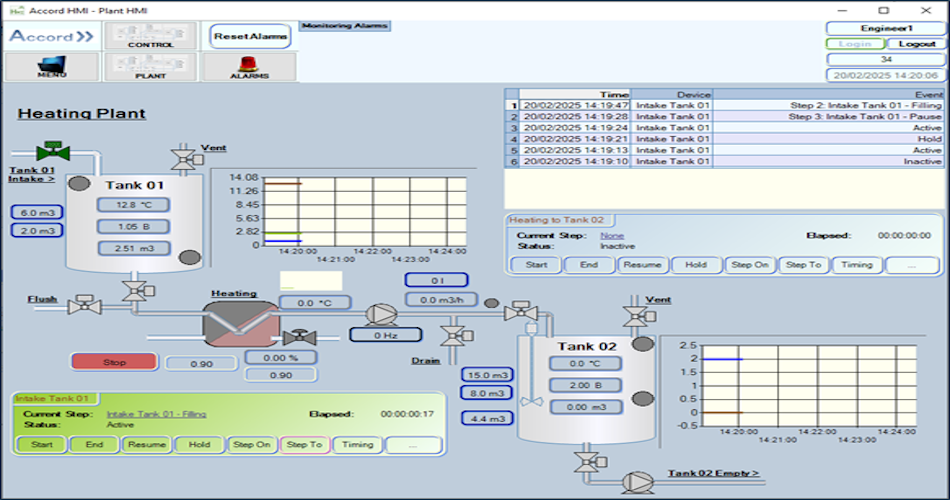

Visualisation:

The HMI Client is very light and is just a client of Server, and can easily be installed anywhere. The configuration of the HMI screens is stored in Server database and is transferred to the client PC when the HMI software is started. All limits, states and security functions are read from Server and SQL, and are automatically up-to-date, without needing to update the client application.

…

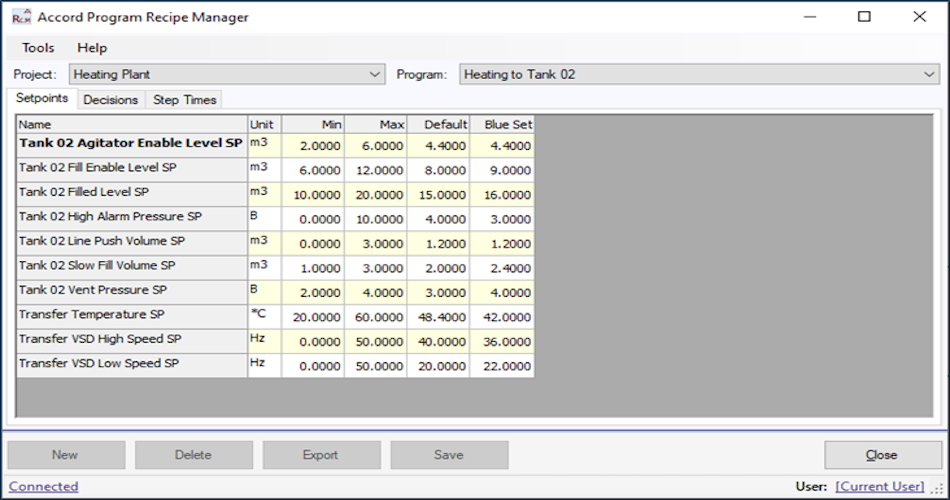

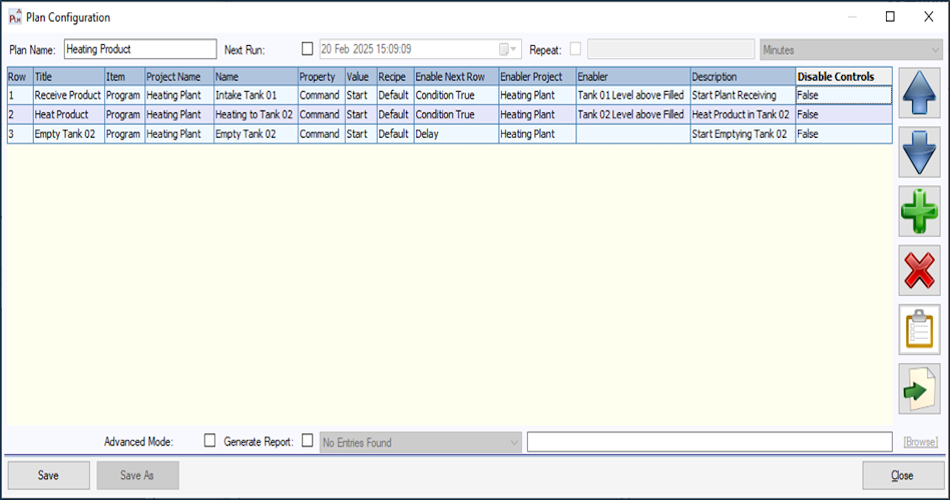

Managing Recipes & Automatic Program Execution:

These modules are clients of Server, and can be installed separately on client PC’s, using functionality working from a managed framework with just configuration required. This means they work from the start and there is no commissioning overhead.

…

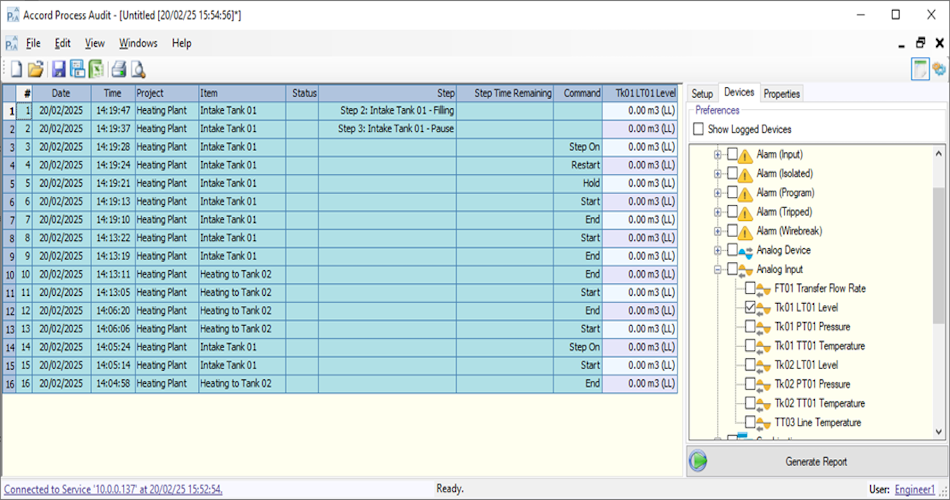

Auditing Historical Information:

The Process and Security audits provide the ability to examine any past status or event. Again, they are clients of server and in effect perform large configurable queries of the process database, converting the settings to SQL Query and returning the data into the framed tables.

Putting in a Hot Standby:

The server redundancy option allows a second PC to act as a hot-standby auto-switchover backup for the Server PC. The selection of the functions as Primary and Partner and the linking is carried out using a drop-down, without any scripts. If the Primary fails the Partner will automatically provide information for the clients. Partner updates settings for objects automatically after a restart of the Primary. Partner will store logging data and transfer the logged data to the Primary PC SQL when the Primary PC returns and it on network again.

…

Quick Screenshot type introduction :

please use the arrows ->